Solar panel discoloration is common. It can hurt the efficiency and look of your solar system. You may have noticed your solar panels changing color over time. This may have raised concerns about their performance and longevity. This problem harms your solar installation’s look and energy output.

To address this issue you need to understand why solar panels change color and how to deal with it effectively. This article will explore the types of solar panel discoloration. It will cover their causes and effects on performance. You’ll also learn about professional repair options and ways to clean solar light panels. By the end, you’ll know how to fix a common solar panel defect. It will keep your system running at its best.

Types of Solar Panel Discoloration

While maintaining your solar panel system you may notice some discoloration. It can affect its appearance and performance. Understanding these issues can help you identify and address them promptly. Let’s explore the most common types of solar panel discoloration:

Yellowing and browning solar panel discoloration

One of the most noticeable forms of discoloration is the yellowing or browning of the solar panels. This issue occurs due to the degradation of ethyl vinyl acetate (EVA), a material used as an encapsulant in the panel. Initially clear the EVA can turn visibly yellow or even brown over time.

This discoloration is due to an uncontrollable chemical reaction in the panel materials. Studies have shown that acetic acid plays a crucial role in turning the EVA encapsulate yellow. This reaction happens between chemicals on the silicon solar cell surfaces and those used to treat the glass.

Prolonged exposure to UV rays can accelerate this process, especially if the EVA is made from lower-quality materials. Solar panels can resist sunlight. However, cheaper EVA parts may have low UV resistance. This can lead to discoloration after a few years of use.

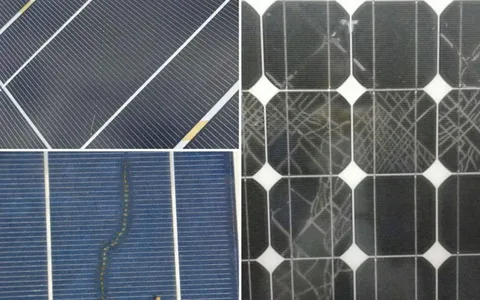

Snail Trails on solar panels

Snail trails are patterns on solar panels that resemble the dark, discolored tracks left by snails. Usually, these trails start to show up three months to a year after installation. They can appear at cell edges, across the cell, between cell busbars, or with framing discoloration, among other places.

Snail trails are a result of moisture and oxygen entering the panels through tiny fractures. In use, the rear sheet foil of the PV modules lets moisture in from the environment. Through microcracks or cell edges, this moisture can subsequently diffuse to the solar cell’s front surface.

Snail trails by themselves don’t drastically lower power output but the microcracks they cause can drastically affect module performance. Studies suggest that snail trails can affect power generation by up to 30% concerning nameplate ratings.

Delamination of solar panels

Delamination occurs when the laminated components of a solar panel become detached from each other. This issue often comes from poor installation. For example, ill-fitted module trim can let moisture into the solar panels. As a result, bubbles start to form between the layers.

Poor manufacturing quality is a significant factor in delamination. Contaminated panel components in production can weaken the bond between layers. This can cause separation over time. Delamination can cause a reduction in the panel’s efficiency and may lead to busbar corrosion.

Hot Spots

Hot spots are areas on your solar panels that become abnormally warm due to overloading over time. These hot spots can emerge when connections between photovoltaic cells face high resistance. This can disrupt the entire string of cells.

There are three main causes of hot spots that you should be aware of:

- Mechanical damage

- Soiling or shading

- Internal module failures

If hot regions are ignored there may be dire repercussions. They may result in solder melting, cell fractures, or even total cell degradation. In severe cases, they can break the protective glass. This increases the risk of moisture seeping in and system failure.

The best way to locate hot places is with thermography. This method produces thermal pictures of the modules, highlighting temperature differences.

Knowing these types of discoloration on solar panels can help. You can monitor your system better and respond to any problems. You can keep your solar panels at peak performance by preventing or fixing issues. Regular inspections and maintenance will help.

Causes of Solar Panel Discoloration

Knowing the causes of solar panel discoloration can help you. It can maintain your system’s efficiency and longevity. Let’s explore the main factors contributing to this issue:

UV Exposure

Sunlight, especially UV rays, significantly discolors solar panels. Over time, UV rays can cause degradation of the materials used in solar panels, affecting both their appearance and efficiency. This exposure can lead to:

- Breakdown of hydrogen bonds in the passivation layer

- Generation of surface defects on solar cells

- Damage to the silicon beneath the passivation layer

UV radiation harms the panel’s surface and its internal parts. It penetrates deep and causes long-term damage.

Moisture Ingress

Water in solar panels causes discoloration and lowers performance. Even with impermeable glass backs, moisture can enter through the edges over 20 years. This moisture ingress can lead to:

- Growth of mold, algae, or lichen on the panel surface

- Formation of “snail trails” along microcracks

- Localized heating and breakdown of cell surfaces

High humidity levels and frequent exposure to rain or fog can accelerate this process. Water vapor, plus other factors, can cause discoloration and lower energy output.

Manufacturing Defects

Poor quality control in manufacturing can cause issues that lead to discoloration.

- Contamination of panel components during production

- Use of low-quality materials especially in the encapsulant (EVA)

- Inadequate UV resistance in cheaper EVA components

These defects can make panels more susceptible to discoloration, especially after the first few years of use.

Chemical Reactions

Uncontrolled chemical reactions within the panel materials play a crucial role in discoloration. The main culprits are:

- Ethyl Vinyl Acetate (EVA) degradation: EVA, used as an encapsulant, can turn yellow or brown due to chemical reactions.

- Acetic acid formation:

- Studies show that acetic acid is the main cause of EVA discoloration. It results from reactions between chemicals on the silicon solar cell surfaces and those used to treat the glass.

The breakdown of additives used to prevent browning and enhance UV tolerance can also trigger these reactions. Poor storage and handling conditions can exacerbate the issue, leading to bleaching and blistering of the EVA film and back sheet.

To mitigate these issues some manufacturers are exploring solutions such as:

- Adding UV-blocking additives to the encapsulant material

- Applying glass coatings to block UV light

- Developing coatings for the front of the cell to reduce UV damage

By understanding these causes, you can take proactive steps to protect your solar panels and extend their lifespan. Regular inspections and maintenance can spot and fix discoloration issues. This can be done before they harm your system’s performance.

Impact of Discoloration on Solar Panel Performance

Solar panel discoloration can have various effects on your system’s performance. Some discoloration may not affect energy output. But, others can reduce efficiency and cause long-term issues. Let’s explore the key impacts of discoloration on your solar panels.

Reduced energy output

The possibility that discoloration in solar panels could result in less energy being produced is one of the main causes of concern. Microcracks in the silicon of the solar cells frequently cause discoloration. These tiny fissures weaken electrical connections. So, there are fewer routes for electrons from the sun to travel. Consequently, less energy enters your home, place of business, or farm and travels to your inverter.

The degree and kind of discoloration can affect how much energy is reduced. Some discoloration may not affect energy output. But, others can noticeably reduce performance. It is crucial to remember that not every discoloration indicates a flaw or decreased effectiveness.

Decreased lifespan of solar panels

Discoloration can signal damage to your solar panels. It may reduce their lifespan. Several factors contribute to this degradation:

- UV radiation exposure: Prolonged exposure to sunlight, particularly UV rays, can cause the degradation of the materials used in solar panels. This not only affects their appearance but can also reduce their efficiency over time.

- Environmental factors: Extreme weather conditions, including cold and hot temperatures, humidity, snow, and ice, slowly contribute to solar panel degradation. These elements can accelerate the discoloration process and potentially shorten the panel’s lifespan.

- Material breakdown: Uncontrolled chemical reactions between lamination materials (such as EVA) and oxygen in the environment can contribute to discoloration. While this may not always directly impact performance, it can be a sign of ongoing degradation.

Warranty implications about solar panels

If you see discoloration on your solar panels, check the warranty. Here are some key points to keep in mind:

While discoloration may affect the appearance of your panels, it doesn’t always indicate a performance issue. Many warranties focus on power output rather than cosmetic changes. Severe discoloration could potentially indicate damage although its presence doesn’t necessarily imply a solar panel defect. Common defects, like hot spots and snail trails can hurt performance and safety.

Different manufacturers may have varying policies regarding discoloration. Some may cover performance drops due to discoloration. Others might not address cosmetic issues.

To protect your warranty rights, it’s essential to document any discoloration you observe and monitor your system’s performance over time. This information can be valuable if you need to make a warranty claim.

Discoloration can affect your solar panels’ performance, lifespan, and warranty. By knowing this, you can make better choices about maintenance and repairs. Regular inspections and performance monitoring can help. They can find and fix issues early. This will ensure your solar investment gives you the best returns.

Professional Repair and Replacement Options

If you see discoloration or damage to your solar panels consider professional repair or replacement. These services can help maintain your system’s efficiency and extend its lifespan.

Cleaning and Restoration Services

For solar panels to operate at their best, regular cleaning and maintenance are required. Dirt, grime, and contaminants can harm your panels. Professional cleaners use specific tools and methods to remove them. Research shows that, without routine cleaning, PV panels can lose over 20% of their performance.

Reputable cleaning services use premium special cleaning supplies to clean solar panels. This preserves your investment. They often use deionized pure reverse osmosis water. It’s eco-friendly and efficient at boosting solar output.

Panel Replacement Process

If your solar panels are severely damaged or worn out, replacement might be necessary. The process typically involves:

It’s important to note that the exact make and model of your original panels may no longer be available. Read about how to recognize fake solar panels. In such cases, the installer will check that the new panel is compatible with your setup. This will maintain optimal performance.

Costs and Considerations

The cost of repair and replacement can vary. It depends on the damage and the services needed. Here’s a breakdown of potential expenses:

- Minor repairs: For issues like broken glass repair or loose connections, you might pay around $20 for small parts or $100 per hour for labor.

- Solar inverter replacement: This can cost up to $250 for microinverters and up to $2,500 for string inverters, not including labor.

- Panel replacement: A single panel could cost between $300-$600, plus electrician fees ranging from $100-$200 per hour.

- Complete system replacement: For a full installation you can expect to pay from $12,900 up to $15,180, with high-end systems potentially costing up to $48,000.

Before repairs or replacements check your warranty and insurance. Some manufacturers may cover performance drops from discoloration. Some people overlook superficial problems solely related to appearance.

Conclusion

Solar panel discoloration is a common problem. It affects both their function and appearance. Solar panel owners can manage their systems by identifying the causes of discoloration. They should take proactive steps to find its forms and effects.

In conclusion, we must treat solar panel discoloration with quick fixes and prevention. There are many ways to fix this, like cleaning, replacing panels, and making warranty claims. Solar panel owners should stay informed and act as needed. This will help their systems produce clean energy efficiently for years to come.